ALPMA GB Limited has been based in the UK since 1987.

Few companies can provide so many solutions and services,

all from one UK-based supplier.

The family consists of machinery for cheese production, cutting/ packaging lines, process technology, soft cheese equipment, project automation, case packing and it’s all supported by UK-based service.

And ALPMA’s APSIS 4.0 – the interactive spare parts catalogue – has revolutionised access to vital components and is available for all ALPMA customers.

ALPMA. On balance, your best solution

The family consists of machinery for cheese production, cutting/ packaging lines, process technology, soft cheese equipment, project automation, case packing and it’s all supported by UK-based service.

And ALPMA’s APSIS 4.0 – the interactive spare parts catalogue – has revolutionised access to vital components and is available for all ALPMA customers.

ALPMA. On balance, your best solution

The ALPMA GB offices get an upgrade!

New solar panels are installed and

they generate more power than

the factory actually uses.

Now fully operational, ALPMA and

it’s customers are protected

against energy price rises and in

addition, is making a positive

contribution to going carbon

neutral.

A complete office refurbishment

creates a better working

environment for all.

And a new training and display

area has been made for the

benefit of staff and customers.

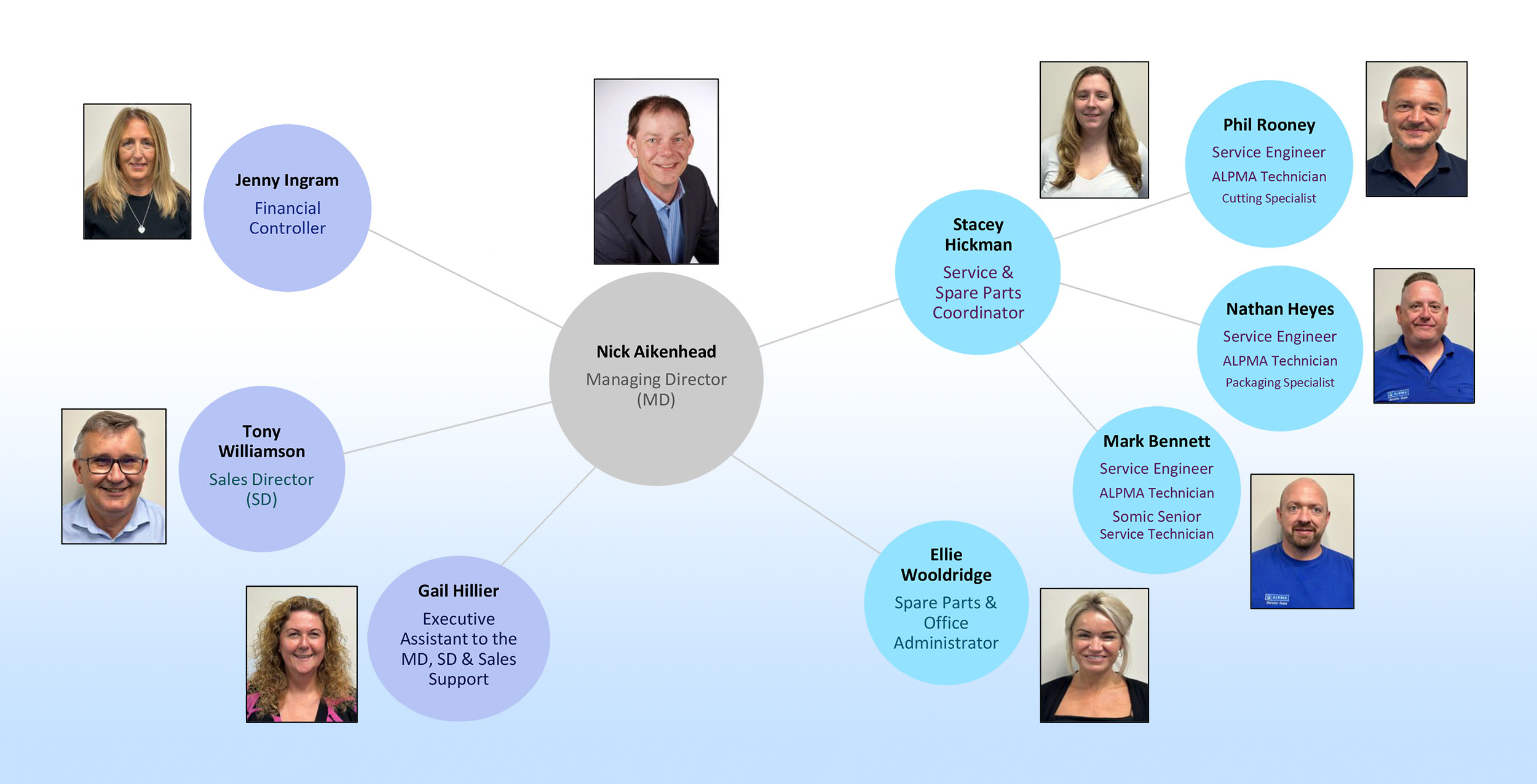

Meet the ALPMA GB team

ALPMA GB Limited products and services

From the head office in

Basingstoke, ALPMA provides a

wide range of solutions.

Click on any picture above to find

out more. Alternatively telephone

01256 467177 or email here.

Cheese moulds and accessories

They have developed unique techniques over the years for perforating, marking patterns, shaping and welding high-performance, high-quality plastic parts and plates.

Click here to see available equipment

Complete solutions under one roof

ALPMA designs and manufactures installations for all kinds of

cheeses and dairy sizes. An ALPMA line is designed on a modular

basis and can therefore be adapted step-by-step to fit a growing

dairy.

Industrial Installations – Continuous Cheese Production of over 1,000,000 litres/day

Automatic milk preparation, the highest levels of portioning exactness with technologically balanced portioning and constant conditions during ripening ensure you unsurpassed yield and therefore the success of your industrial cheese Production.

Medium-sized Installations – Continuous Cheese Production up to 100,000 litres/day

High flexibility, variety of cheese types and innovative adjustment are the characteristics of today’s medium-sized dairies. Curd preparation is carried out either fully continuously using our modern Coagulators or in traditional cheese vats.

Small Installations – Continuous Cheese Production up to 10,000 litres/day

With comprehensive cheese vats from 400 litres, efficient production circuits can be created. Ideal for milk processing of up to 10,000 litres/day and for all soft cheese types.

Industrial Installations – Continuous Cheese Production of over 1,000,000 litres/day

Automatic milk preparation, the highest levels of portioning exactness with technologically balanced portioning and constant conditions during ripening ensure you unsurpassed yield and therefore the success of your industrial cheese Production.

Medium-sized Installations – Continuous Cheese Production up to 100,000 litres/day

High flexibility, variety of cheese types and innovative adjustment are the characteristics of today’s medium-sized dairies. Curd preparation is carried out either fully continuously using our modern Coagulators or in traditional cheese vats.

Small Installations – Continuous Cheese Production up to 10,000 litres/day

With comprehensive cheese vats from 400 litres, efficient production circuits can be created. Ideal for milk processing of up to 10,000 litres/day and for all soft cheese types.